Pedra Branca is Avanco’s second Project, which will take the company to 50,000 tonnes of annual copper production, realising the ambition to be a mid-tier copper producer. The Project is targeting first commercial production in 2020. Pedra Branca is 100% owned by Avanco.

Pedra Branca is divided between the East and West Zone. The East Zone is the first zone being prepared for production, targeting 24,000 tonnes of copper and 16,000 ounces of gold annually. It is envisaged that this will be complemented with additional production from the Pedra Branca West Zone by an additional 10,000 tonnes of copper and 6,500 ounces of gold annually.

The empirical data in this section of the website relates primarily to Pedra Branca East as published in the Pre-Feasibility Study Summary from May 2017.

Pedra Branca was acquired from Xstrata in 2012 for 15% of the enlarged share capital of the Company. Following the acquisition of Xstrata by Glencore, these shares are now held by Glencore.

GEOGRAPHY & ENVIRONMENT

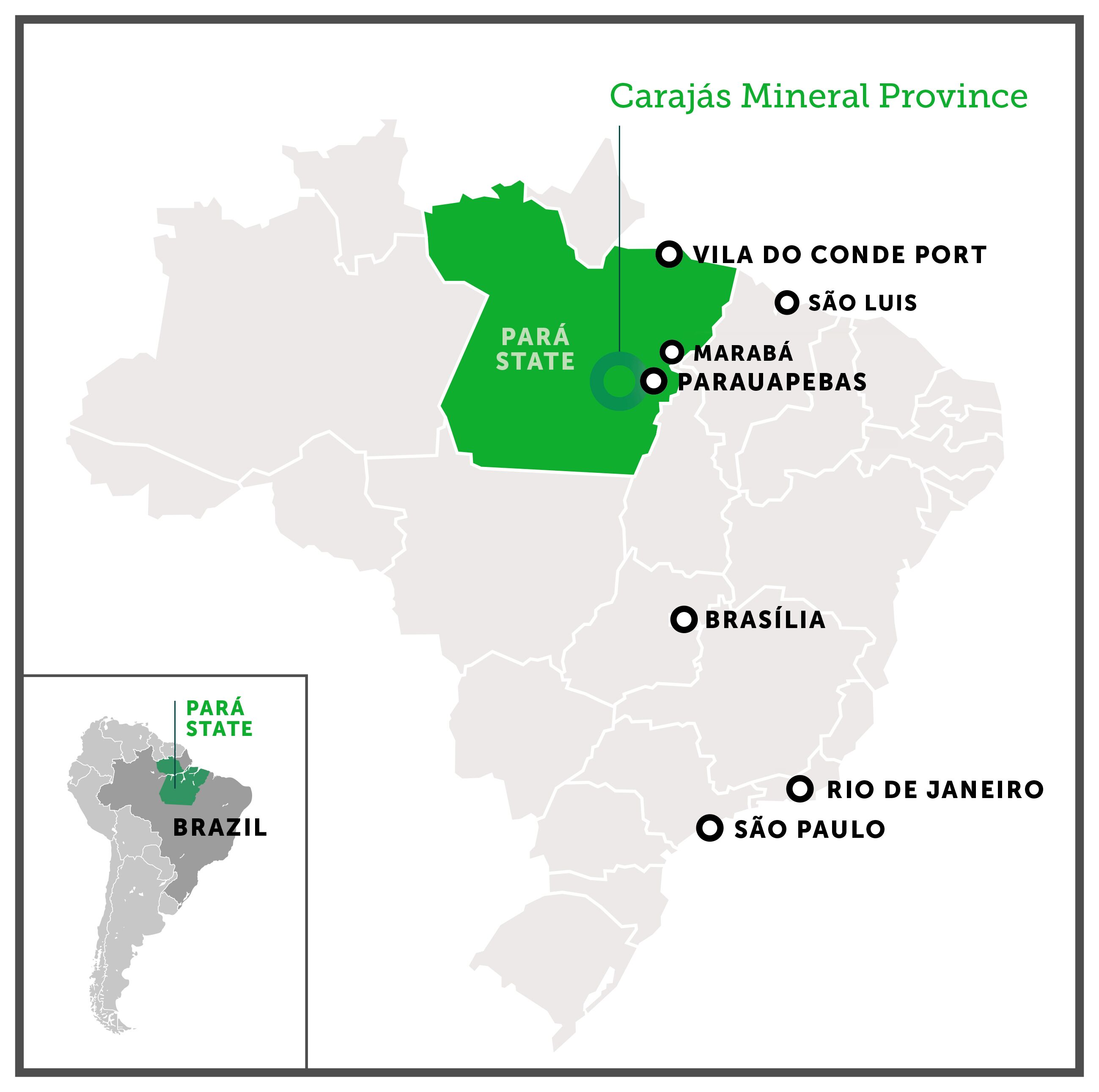

Pedra Branca is located in the southern part of the Carajás in the state of Pará in the North of Brazil. situated just under 100 kilometres south of Parauapebas and 30 kilometres east of Canaã.

Pedra Branca benefits strategically from its situation. Close to the established mining city of Parauapebas and the town of Canaã, like it’s smaller sister, Antas, the development and operation of Pedra Branca will benefit from direct access to established world class infrastructure and all the nearby support services of a mining focused region. In particular, Pedra Branca benefits from some of the most modern and large capacity infrastructure available globally due to the nearby neighbours, the Sossego Copper Mine and the recently completed SD11 operation, the largest iron ore mine in the world.

The topography around Pedra Branca is flat and facilitates the development and operation of a mine, processing plant and the necessary support infrastructure.

The climate in the region is tropical and humid with two distinct seasons. The dry season extends from June to September and the rainy season from October to May. Annual rainfall is approximately 1,600mm.

GEOLOGY

Pedra Branca East (PBE) is an Iron Oxide Copper Gold (IOCG) type deposit located within the Carajás Basement, and is hosted predominantly by diorite and sheared granite. Country rocks are mostly biotite-gneisses (ortho-gneisses), while pegmatite dykes are abundant in proximity to the ore zones.

This deposit occurs along an E-W striking regional shear zone, which is represented by metres wide mylonitic zones marked by intense silicification. This shear zone is regionally crosscut by north-south, northeast and northwest striking faults.

Pedra Branca East (PBE) is an Iron Oxide Copper Gold (IOCG) type deposit located within the Carajás Basement, and is hosted predominantly by diorite and sheared granite. Country rocks are mostly biotite-gneisses (ortho-gneisses), while pegmatite dykes are abundant in proximity to the ore zones.

This deposit occurs along an E-W striking regional shear zone, which is represented by metres wide mylonitic zones marked by intense silicification. This shear zone is regionally crosscut by north-south, northeast and northwest striking faults.

Two main ore types are identified at Pedra Branca:

- Semi-massive, high grade breccia matrix ore: consists of hydrothermal breccia zones with matrix filled by magnetite and chalcopyrite, plus subordinate pyrrhotite and less pyrite. The clasts are made of altered host rock and coarse amphibole. The typical range of assays for this ore type is between 4.0% copper to 10.0% copper.

- Disseminated ore: a low to medium grade ore which envelops the high-grade zone. It consists of the same sulphide assemblage, which is also associated with magnetite that occurs as fine disseminations in the host rock, sometimes following the foliation, and also filling veinlets and fractures. The typical assays range from below cut-off grade (0.9% copper) to 2.5% copper.

MINERAL RESOURCES

CSA Global was commissioned by Avanco to complete Mineral Resource estimates for Pedra Branca East (PBE) and Pedra Branca West (PBW) soon after the acquisition of the project in 2012.

In May 2016, CSA Global updated the Mineral Resource estimate for PBE (refer to ASX Announcement “Resource Upgrade Advances Pedra Branca Development Strategy”, 26 May 2016, for Competent Person’s Consent, material assumptions and technical parameters underpinning the PBE Mineral Resource estimate, including JORC Table 1, Sections 1, 2, and 3).

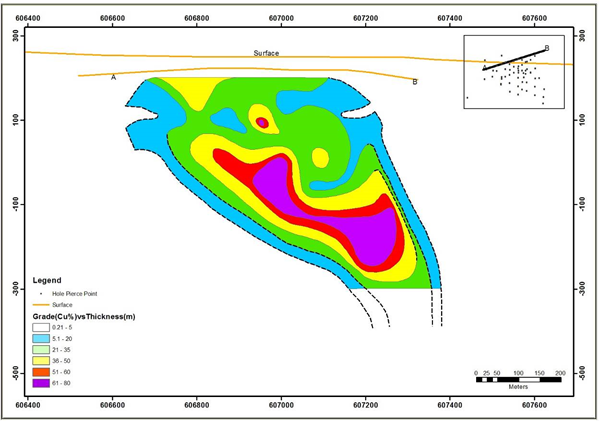

Three dimensional solids were created by joining sectional interpretations of the copper mineralisation, which were based on a nominal lower cut-off grade of 0.2% copper for the disseminated mineralisation and 1.0% copper for the high grade domain. These solids were used to constrain the Mineral Resource estimate. A block model was created using 10.0m east by 5.0m north by 10.0m RL parent blocks. Ordinary Kriging was used to estimate grades into the blocks from composited sample data. A 1.0m composite data set was used for variography and grade estimation.

The PBE Mineral Resource is classified and reported in accordance with the JORC Code 2012. Mineral Resource classification is based on data quality, confidence in the geological interpretation, drill spacing and geostatistical measures.

Mineral Resource Estimate for Pedra Branca East, May 2016

| PEDRA BRANCA EAST – Mineral Resource as at May 2016 | |||||||

| CLASSIFICATION | TYPE | ECONOMIC CUT-OFF Cu % |

TONNES (Mt) | COPPER (Cu %) |

GOLD (Au g/t) |

COPPER METAL (kt) |

GOLD (koz) |

| Measured | PRIMARY | 0.90 | 1.98 | 2.7 | 0.7 | 53 | 43 |

| Indicated | PRIMARY | 0.90 | 5.72 | 2.8 | 0.7 | 162 | 123 |

| Measured + Indicated | 7.70 | 2.8 | 0.7 | 215 | 166 | ||

| Inferred | PRIMARY | 0.90 | 2.78 | 2.7 | 0.6 | 75 | 55 |

| TOTAL | 10.48 | 2.8 | 0.7 | 289 | 221 | ||

Notes:

- The Mineral Resource was estimated within constraining wireframe solids created using a 0.2% and 1.0% Cu cut-off grades for the low grade and high grade domains respectively.

- The Mineral Resource is globally reported above 0.9% Cu assuming underground mining methods.

- Due to the effects of rounding, the sum of individual values will not necessarily equal the total.

MINING

Geotechnical and Hydrology

Initial geotechnical and hydrological investigations have indicated that the majority of the mine openings will be in a hydro-stratigraphic unit with low conductivity and very little water storage capacity in an extremely competent geotechnical domain with high Rock Quality Designation factors. The mechanical strength of the rock mass will allow openings of significant dimensions. For the proposed stope heights of 30m, a maximum stope length of 150m is recommended. Further, specific geotechnical, investigations will form part detailed project design.

Mining Method Selection

Underground mining was selected after a pit optimisation study returned very low recovery of mineral resources at a high strip ratio.

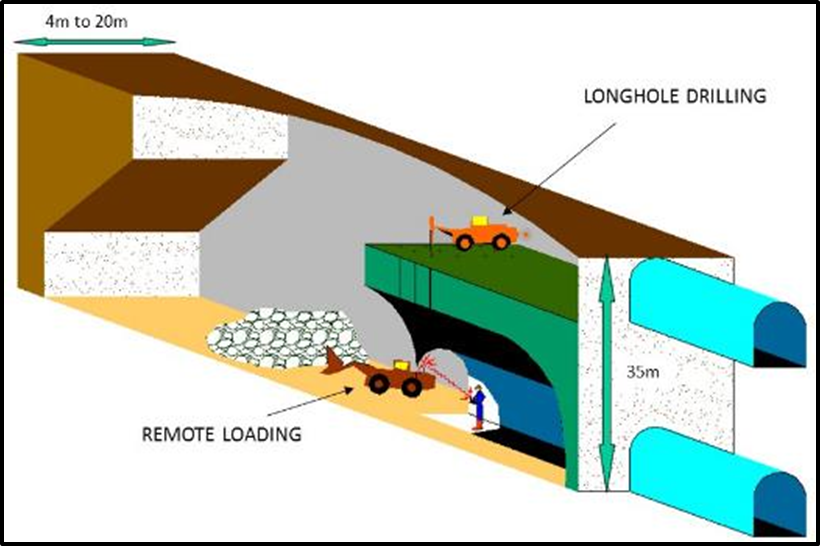

Sublevel open stoping (SLOS) with delayed filling was selected as the most appropriate mining method for PBE, as the mineralisation is relatively wide and competent, is steep dipping with strong wall rocks and has favourable operating and preproduction capital costs. Sublevel intervals will be 30 m sill to sill. The variant of SLOS to be employed at Pedra Branca is termed “bench and fill”, this minimises waste development required and allows the use of ‘non- entry’ mining techniques using radio remote controlled loading from the open stope.

Each stope includes a drill level at the top and an extraction level at the bottom, developed in ore longitudinally along the hanging wall contact with the drive then enlarged to the footwall contact ahead of stoping. Geotechnical analysis indicates that ground support will vary with ground conditions, but the majority of the stopes will require support by means of 2.4m bolts supplemented by the installation of cable bolts in wider areas.

Once stope development to limits is complete, a slot raise is mined between the two sub-levels and progressively blasted to full width. With wide orebody widths, the sharp hanging wall contact, good interpretation and with modem drilling equipment, dilution due to drilling accuracy will be minimal.

Blastholes will be loaded with emulsion and shot in one to three row blasts to monitor blasting practices and maximize effective work time.

Large capacity load-haul-dump (LHD) units remove broken muck from the extraction elevation and either transport to a “transfer stock point” on the level or dump directly into mine trucks. It is expected that contracted 40 tonne articulated trucks will be used during the development phase and larger capacity, more efficient machines will be used once the mine moves to a higher production rate. The LHDs will be operated by radio remote control allowing loading inside the open stope while the operator remains in a safe location.

Access

Access to the Pedra Branca East mine will be by a decline from the surface with dimensions of 5.5 m x 5.5 m sufficient for the use of 50t to 63t trucks. It will be developed in the footwall granites. To enter competent granite quickly the decline gradient will initially be 15%, reducing to 12.5% once sufficient rock cover is achieved. The decline will be provided with 8m wide “passing bays” at suitable intervals and initially carry the mine services, although these will be re-routed through an intake ventilation raise at a later stage.

Development will be carried out by contractors using standard trackless underground equipment with a twin boom electro-hydraulic jumbo being employed for drilling. Removal of blasted material will be by means of a LHD machine loading to “re-muck” positions mined at suitable intervals. This will clean the face efficiently and ensure that reasonable development rates are achieved.

Ramp development ventilation will be by means of a surface mounted auxiliary axial fan forcing through ventilation ducting to the working face. Initially sub-level development will be ventilated by means of a combination of series ventilation and “Tees” from the main system until an upcast raisebore completes the first circuit.

Box Cut and Portal

The location of the box-cut and portal has been chosen based on ground conditions during the wet season, the thickness and profile of the saprolite and surface topography. The box-cut and portal have been completed in late 2016.

Sub Levels

Access cross cuts from the decline to the orebody will be driven at a 5.5m x 5.5m profile and are designed to provide a position for a mobile substation and a stocking position for development/stoping ore.

Sub-level development will then be undertaken on a 5m x 5m cross section in ore. Support of sub-levels will be by means of bolts, supplemented by cable bolts when the level is enlarged to full ore width ahead of stoping.

Production

The mine production stage requires footwall drifts to be mined in granite to provide sufficient stoping faces to achieve the required production rate. Typically, four cross cut accesses will be mined on each sub-level to provide a minimum of 4 faces retreating each way towards the access.

Stopes are sequenced so that one side can be stopped for filling, whilst the other side continues producing. Once the filling is complete to within 5m of the back, “re-slotting” will take place followed by enlargement and production. On completion of the stoping and filling of one side of the central access, production moves up, with the drilling drift of the previous level becoming the loading drift of the upper stope.

PROCESSING

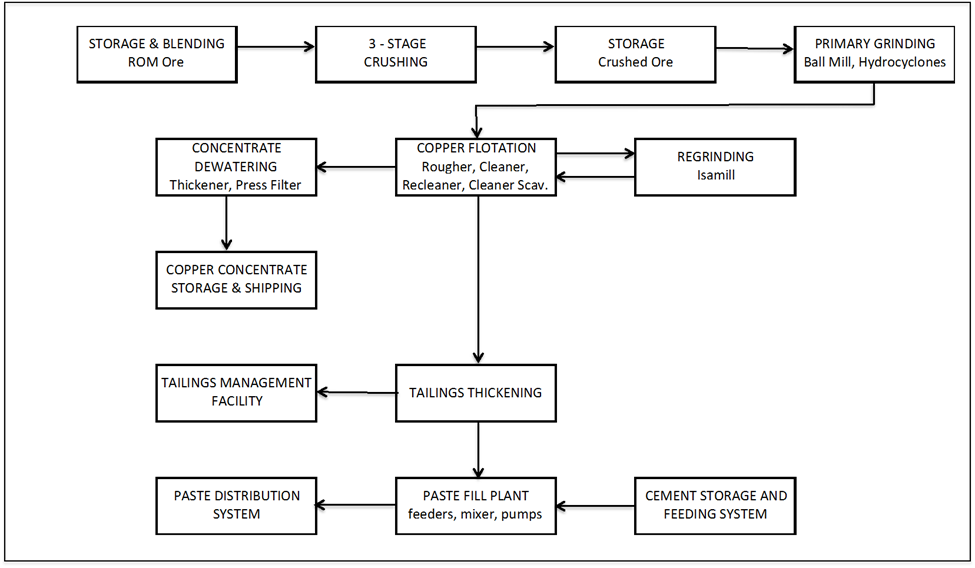

A 1.2 Mtpa process plant will be constructed at Pedra Branca and will be similar to the Antas plant now in production. This plant will consist of three stage crushing, single stage ball milling, traditional copper rougher / cleaner / cleaner scavenger and recleaner flotation circuit, with early production of final concentrate on the first rougher cell. Concentrates from the other rougher cells will be reground before entering the cleaner circuits. Copper concentrates will be dewatered to approximately 8% moisture, using a high rate thickener and filter press.

Tailings will be thickened and pumped to either the paste fill plant or to a conventional TMF, with tails being beached along the upstream face of the impoundment wall. The TMF has been sized to cater for two consecutive high rainfall years. Water will be reclaimed for process use from the TMF using a floating pump pontoon.

The paste fill plant will further densify the tailings prior to mixing with cement and being pumped underground for stope filling. Over mine life it is expected that approximately 5.7Mt of paste will be required, with approximately 4.4Mt of tailings reporting to the TMF.

Annual production is expected to be about 24kt Cu and 16kOz Au contained in 28% Cu concentrates.

The concentrate analysis has shown that any deleterious elements present are below levels which would attract penalties.

PRODUCTION & GUIDANCE

Pedra Branca is targeting two development stages, namely 24,000 tonnes of copper and 16,000 ounces of gold annually from Pedra Branca West with first commercial production in 2020, followed by a complementary 10,000 tonnes of copper and 6,500 ounces of gold annually from Pedra Branca West.

Achieving these targets is dependent on achieving the following deliverables, namely:

2017

- Pre-Feasibility Study

- Project Management Appointments

2018

- Definitive Feasibility Study

- Environmental and Regulatory Licensing

- Underground Construction Commences

- Pedra Branca West Study Commences

2019

- Plant Construction Commences

2020

- First Production

Future

- Pedra Branca West Production